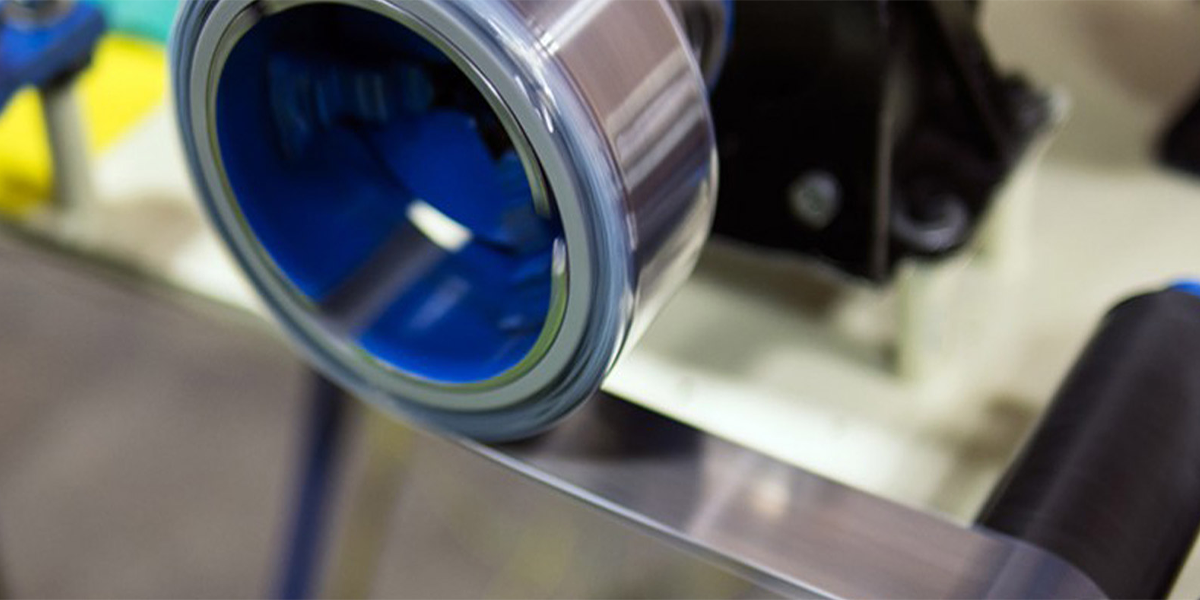

We provide the same quality through every blade with compression forming technology.

Before all our products are delivered to the customers , we are checked and tested. Each produced Blade Master doctor blade is sent by issuing an analysis certificate indicating that it has successfully passed through quality controls.

We produce “cut to length” blades to our customers upon request. By our special cutting machines ,our customer will not have to spend time and labor force by cutting Dr. Blades to use for their printing lines. By cutting the blades to the proper holder length, we save our customers from damaging the blades, wasting material on inaccurate cutting and protecting them from possible injuries that may occur during cutting process.

According to customer request , the used doctor blade are analyzed in our laboratory and your doctor blade usage details are presented to you as a report. In this way, we enable more efficient use by determining the pressure applied during use and your adjusted angle measurements.

BLADE MASTER doctor blades are wrapped with polyethylene film to increase protection and are offered to you in plastic boxes. In this way, the blade is protected against rust; it allows to keep the same quality in your stocks.